Bring Your Products to Life

Get your products to market faster by benefiting from our in-house end-to-end services.

We can take your ideas from prototype to mass manufacturing.

Trusted by

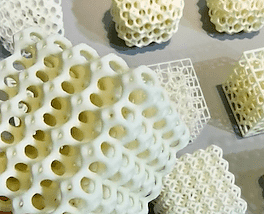

Our Manufacturing Services

Injection Molding

T1 samples manufactured in as fast as 10 days with low minimum order quantities.

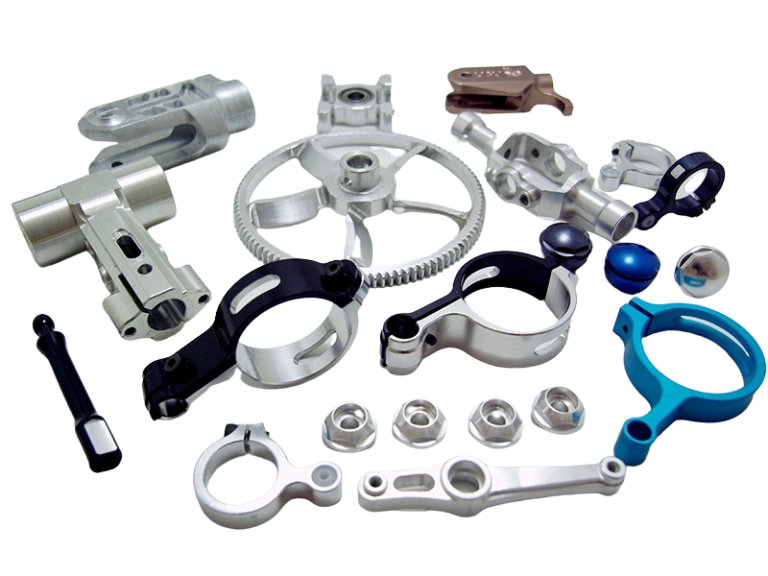

CNC Machining

Tight tolerances and finishing capabilities in as fast as 2 days.

Sheet Metal Stamping

Add multiple finishes to your part such as anodizing or powder coating.

End-to-End Manufacturing

RP Group combines leading technologies and insight across multiple industries to help transform the way your products are made.

Productization

APQP and PPAP Mold Making Check fixtures

Assembly

PCBA assembly Automation Types of in house assembly

Testing & Validation

Age testing Performance testing DVP planning

Supply Chain Management

Materials importing Component sourcing

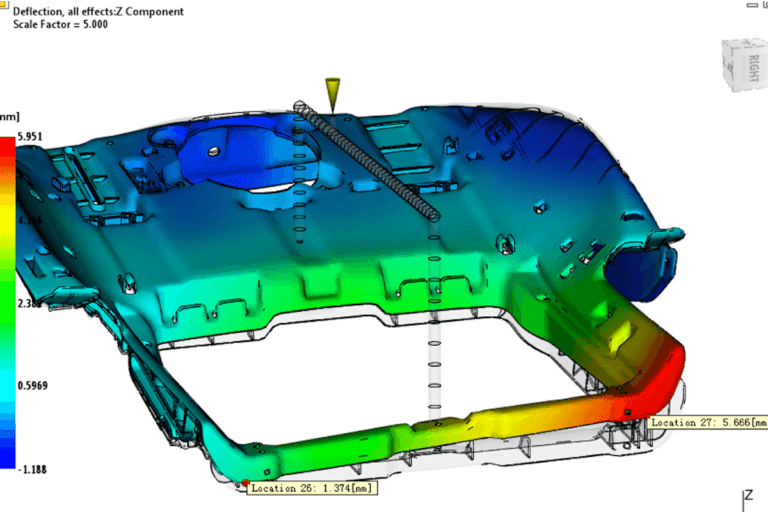

Design for Manufacture (DFM) is important part of product development to save money and improve quality

Modern Manufacturing 4.0

RP Group is always innovating to make it easier for customers to bring their projects to market by using the latest automation and customized AI driven software.

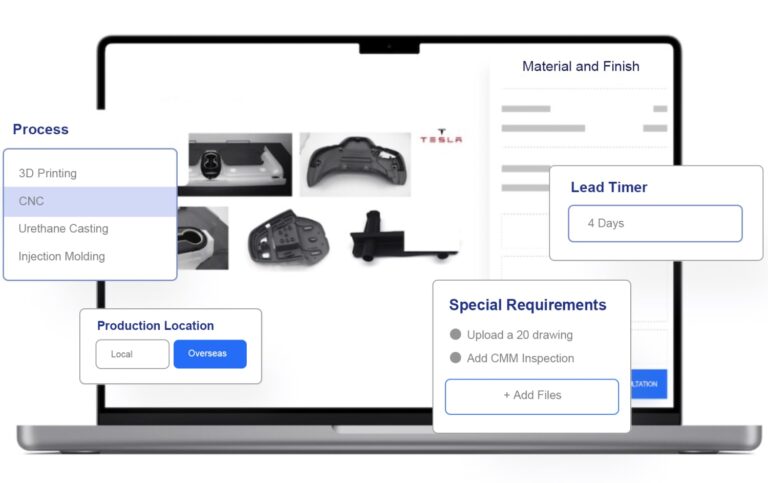

Online instant quoting

Prototyping is all about speed so using our online portal, customers can upload their data and get instant feedback on costs and place an order with less hassles.

- Select from a wide range of materials.

- Compare pricing options instantly

- Manage quotes and orders in our online portal

DFM and DFA analysis

RP has more than a decade's experience in launching projects from various industries using a wide range of processes.

Book a time with one of our manufacturing engineers to discuss your new project.

- Free Design for Manufacturing (DFM) report

- Free Design for Assembly (DFA) analysis to save costs and improve quality

- Get a FREE 1 hour consultation for your project.

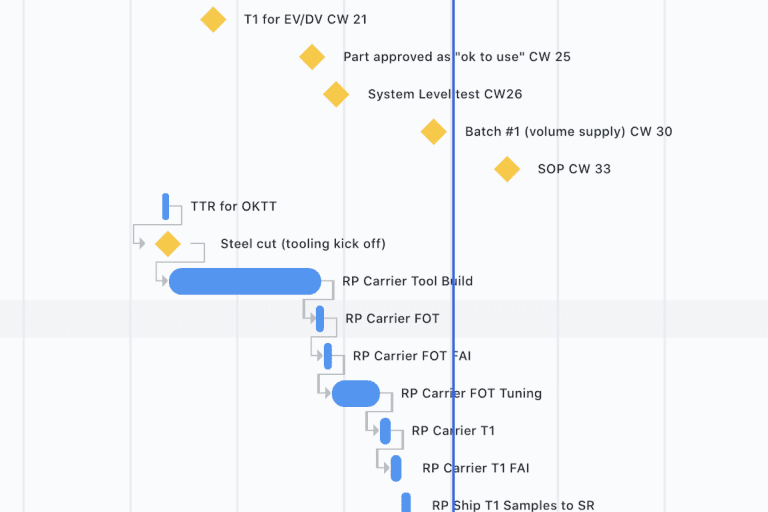

Project management portal and transparent traceability

Keep track of all of your projects on-demand for updates, status and tracking your shipments. The online portal provides a great way to manage complex projects and make seamless communication.

- Track the progress of your project

- Photos and videos of your parts before they ship

- Quality inspection reports online